Recently Iíve been using the Caswell Copy Cad system and thought an unbiased report might be of some interest to others contemplating such a task.

When I started restoring my í67 Triumph Daytona motorcycle, I had all this hardware that was in pretty tough shape. My very understanding wife bought me an Eastwood tumbler set for Christmas, so I carefully sandblasted and/or tumbled the hardware to make it look nice. Then I came to the realization that it was going to rust if I ever took the bike out in the rain, and what are the chances of that not happening in the Seattle area?

I checked into the local plating outfit, and they wanted $110 minimum lot charge, could be more, plus 2-3 weeks lead time. On top of that, I would have had to dump all my neat little baggies of hardware into one bin, and Lord knows if I could ever figure out what was what afterward.

So I decided to buy Copy Cad from Caswell (Caswell Plating) to see how it would work. I was told that if I left out the brightener it would give the flattish gray finish that I wanted to achieve. The three gallon kit was about $260. By the way, check out the British fastener/tool section of their site. Different company, same building, have interesting stuff. I bought their Whitworth tap and die set for my project. The taps and dies seem decent, but the handles were not the highest quality.

The Caswell manual is really good. Goes into detail and theory about plating, along with a lot of practical tips about how to do things. My only comment is that since it covers all of their products, it was a little confusing to distill it down to just what I needed to know for Copy Cad. I called with a list of questions, and they were very helpful in answering them.

Once you buy the kit though, you need other stuff. I spent a day driving different places to accumulate an aerator pump (pet shop), brass wire (Lowes), rubber (not latex) gloves, distilled water, beads (fishing store), copper tubing, and a number of other little things. You also need a power supply for the plating, but since Iím a geek, I had a couple to use. I did find out that a typical lab supply needs some series impedance to regulate properly in this application. The power supply was one of the reasons I didnít get the Eastwood kit. I donít believe that Eastwoodís flashlight battery approach as power is adequate, that made me wonder about the whole kit.

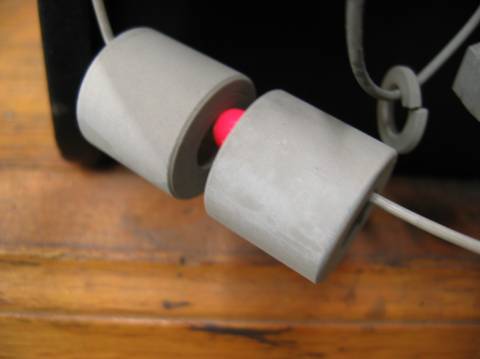

This is what the plating setup looks like:

I did find out that an extra heater would be nice, the degreasing tank should ideally be 190 degrees (at least 140), and the included heater only gets it up to about 160 degrees in ambient conditions.

So to plate each part, it needs to be prepared. I think bead blasting would be best, but I used sandblasting or tumbling. Then, for some parts I also used a plastic or wire brush on a grinder to prep them. The plastic brush is included in the kit.

Once they are prepped, it is necessary to compute the number of square inches of surface area to be done. I wrote an Excel spreadsheet to compute this. Once you know the square inches of the batch, you can compute the current (25mA per square inch).

The parts go into the degreaser tank for awhile, you then mist them with water to ensure there is no beading. Then they go into the plating tank for about 30 minutes. Once done with that, you dunk rinse them, then blow off the big drops, and let them sit for awhile (they can show a finger print for the first couple of hours).

This is how they look when coming out of the plating operation:

As you can see, they are very dull, more so than I wanted. So, the final step is to hand steel wool each part, although bead blasting might do the same thing. This is kind of tedious. You quickly learn that there are eight sides on every not and bolt, and a lot of bolts and nuts, even on a motorcycle. Did I mention there are eight sides of every bolt and nut?

Anyway, this is what a typical fastener looks like when done:

Itís what I wanted and they look pretty good, especially when you arenít focused in on any one particular part as in the picture. Iíve also done brackets, and they seem fine too. Caswell sells other solutions that will apply a color (like a yellow tint) if thatís what you are after. Presumably you can do carburetor bodies and other pot metal parts as well, I havenít tried though. If you use the included brightener solution in the plating tank, it is supposed to give the bright finish one associates with normal Cad plating.

Well, I managed to spend about three times as much money and a huge amount of time (did I mention there are eight sides on every nut and bolt?) to do the project compared to leaving it to the pros, and I still have a few bags to go. Still, itís interesting to do stuff yourself, and Iím set up for in the future. From reading the manual, I see you can also unplate parts by reversing the electrical current. Interesting. I also do my own powder coating via the Eastwood system, but thatís another story.